Sani-Flow Temperature Sensor Specifications

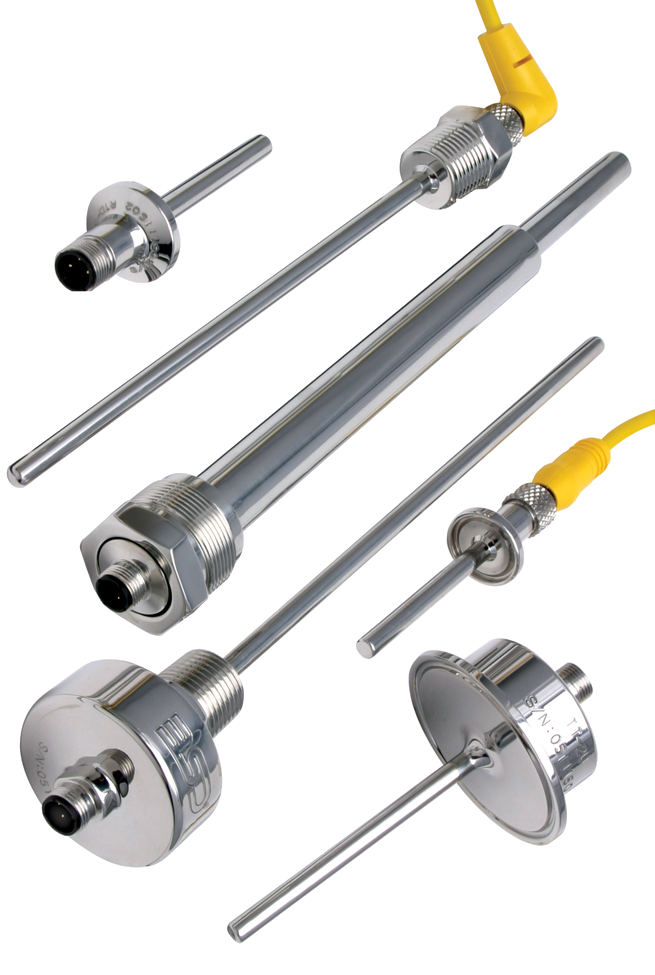

RTDs & Temperature Transmitters

Sanitary and industrial RTDs and temperature transmitters

3-A (1), NEMA 4X, IP67, ISO 9001:2015

3-A (1), NEMA 4X, IP67, ISO 9001:2015

Conforms to 3A 74-05 Sanitary Standards for Sensors and Sensor Fittings and Connections Used on Milk and Milk Products Equipment.

Conforms to 3A 74-05 Sanitary Standards for Sensors and Sensor Fittings and Connections Used on Milk and Milk Products Equipment.

3-A Sanitary Standards, Inc. (3-A SSI) is an independent, not-for-profit corporation dedicated to advancing hygienic equipment design for the food, beverage, and pharmaceutical industries.

IP67 - IP means "Ingress Protection". IP67 enclosures are rated as "dust tight" and protected against the effects of temporary immersion in water.

Yes

Yes

Chicago Stainless Equipment Sensors can be Cleaned in Place (CIP) and/or Steamed in Place (SIP) without damaging the sensor.

Just be certain not to exceed the operating temperature limits.

Chicago Stainless Equipment Sensors can be Cleaned in Place (CIP) and/or Steamed in Place (SIP) without damaging the sensor.

Just be certain not to exceed the operating temperature limits.

Yes(2)

Yes(2)

Chicago Stainless Equipment Sensors can be Autoclaved to 150°C (302°F) maximum. Temperature Transmitters

electronics must be removed from housing prior to autoclave.

Chicago Stainless Equipment Sensors can be Autoclaved to 150°C (302°F) maximum. Temperature Transmitters

electronics must be removed from housing prior to autoclave.

-50° to 150°C (-58° to 302°F)(3)

-50° to 150°C (-58° to 302°F)(3)

This is the temperature limit of the product being measured which the sensor is capable of measuring.

This is the temperature limit of the product being measured which the sensor is capable of measuring.

For higher process temperature applications, please consolt factory.

-30° to 150°C (-22° to 302°F)(3)

-30° to 150°C (-22° to 302°F)(3)

This is the temperature limit of the product being measured which the sensor is capable of measuring.

This is the temperature limit of the product being measured which the sensor is capable of measuring.

For higher process temperature applications, please consolt factory.

-25° to 125°C (-13° to 257°F)(4)

-25° to 125°C (-13° to 257°F)(4)

This is the temperature range of the environment which the sensor can safey be exposed to. If the

sensor should go above or below these temperature limits, the instrument will not operate properly.

This is the temperature range of the environment which the sensor can safey be exposed to. If the

sensor should go above or below these temperature limits, the instrument will not operate properly.

-25° to 85°C (-13° to 185°F)

-25° to 85°C (-13° to 185°F)

Std. 12mm Industrial Connector

Std. 12mm Industrial Connector

All Chicago Stainless Equipment sensors come with a standard 12mm industrial connector with gold plated contacts. This allows for quick and easy installation and removal.

No complicated leaking wiring heads or tools required. Simply plug in the connector, hand tighten, and go. Cables can be purchased separately

from CSE or from most industrial supply warehouses.

All Chicago Stainless Equipment sensors come with a standard 12mm industrial connector with gold plated contacts. This allows for quick and easy installation and removal.

No complicated leaking wiring heads or tools required. Simply plug in the connector, hand tighten, and go. Cables can be purchased separately

from CSE or from most industrial supply warehouses.

Temperature Transmitter Electronics (NFC Programmable) Standard

± 0.15% of Scale

± 0.15% of Scale

Accuracy is defined as the conformity of an indication to its true value. Accuracy is ± (plus or minus) a stated value across the full

range. For example, a temperature transmitter with an accuracy of ±0.2% of full scale that has had its range set to 50 to 120°C, would

mean that the sensor can be off no more than 0.14°C ( 0.002x[120-70]=0.14) above or below the actual temperature.

Accuracy is defined as the conformity of an indication to its true value. Accuracy is ± (plus or minus) a stated value across the full

range. For example, a temperature transmitter with an accuracy of ±0.2% of full scale that has had its range set to 50 to 120°C, would

mean that the sensor can be off no more than 0.14°C ( 0.002x[120-70]=0.14) above or below the actual temperature.

-30°C to 150°C (-22°F to 302°F) factory or field rangeable(5)

-30°C to 150°C (-22°F to 302°F) factory or field rangeable(5)

This is the standard range at which the transmitters are set by the factory. Temperature transmitters can be ordered

with a different range if desired, or they may be adjusted in the field by a knowledgeable technician.

This is the standard range at which the transmitters are set by the factory. Temperature transmitters can be ordered

with a different range if desired, or they may be adjusted in the field by a knowledgeable technician.

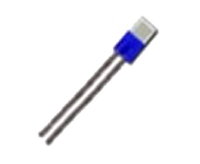

RTD Element

Thin-film RTD element potted in probe with thermally conductive paste

Accuracy is defined as the conformity of an indication to its true value. Accuracy is ± (plus or minus) a stated value across the full

range. For example, a sensor that has an accuracy of ±0.15°C would mean that the sensor can be off no more than 0.15°C above or below the

actual temperature.

Accuracy is defined as the conformity of an indication to its true value. Accuracy is ± (plus or minus) a stated value across the full

range. For example, a sensor that has an accuracy of ±0.15°C would mean that the sensor can be off no more than 0.15°C above or below the

actual temperature.

Alpha = 0.00385 Ohms/Ohm/°C

Alpha = 0.00385 Ohms/Ohm/°C

The temperature coefficient describes the average resistance change per unit of temperature from the ice point to the boiling point of water.

α = (R

Max. R0-Drift 0.04% after 1000 hrs at 500°C (932°F)

Max. R0-Drift 0.04% after 1000 hrs at 500°C (932°F)

The stability of a sensor is its measure of how repeatable the instrument is over time.

The stability of a sensor is its measure of how repeatable the instrument is over time.

(1) Sanitary connections only. For a detailed list of sanitary fittings please consult factory

(2) Autoclave to 132°C (270°F) maximum - electronics MUST be removed from housing

(3) High Temperature Option increases maximum process temperature to 204°C (400°F).

For higher temperature applications please consult factory

(4) Verify temperature limit of mating cable

(5) By a knowledgeable/qualified technician using NFC and a smart phone or tablet and INOR Connect app

Available for free download on App Store, Google Play store and Huawei AppGallery

(6) Tolerance in °C = ±0.15 + 0.002│t│ :where t = temperature

Send us an e-mail

Send us an e-mail